Machines are shipped directly to the customer from the Axiom warehouse. You will be contacted with the shipping costs to ship to you.

The latest Axiom Precision AutoRoute Pro V6 Series of CNC routers maintains the beloved features of Axiom's Pro series while enhancing performance with 48V stepper motors for increased holding torque, an upgraded cooling system, and superior spindle performance courtesy of an advanced VFD upgrade.

Introducing the Enhanced Pro V6 Series: Elevating Efficiency and Performance in CNC Routers

The Pro V6 showcases a fresh aesthetic and is now stronger, faster, and easier to maintain than ever before.

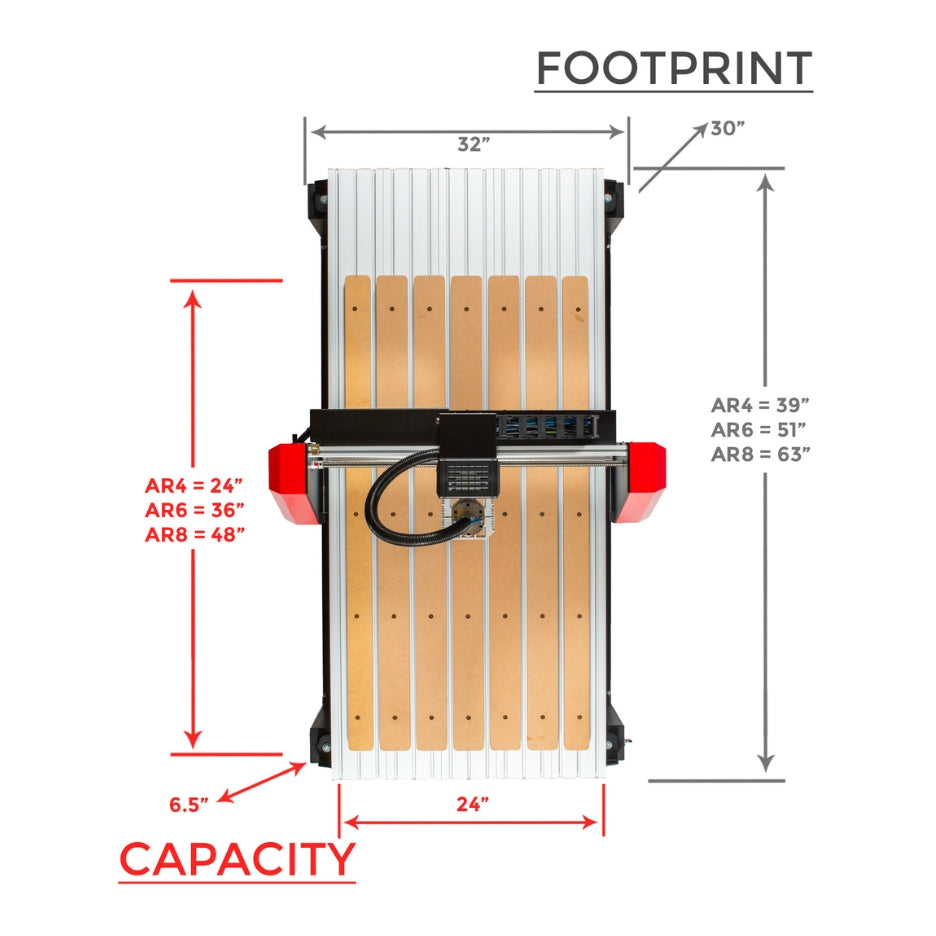

Incorporating 4-axis functionality, potent electro spindle capabilities, and rotary machining adaptability, the revamped Pro series delivers within a compact industrial framework.

Featuring a generous 6.5 inches of gantry clearance and a quiet yet powerful 3HP electro-spindle equipped with an integrated liquid cooling system, the Pro V6 series CNC routers stand at the forefront of efficiency and performance.

Efficiency and Precision Redefined: Discover the Axiom Pro V6 Series CNC Routers

Every machine in the Pro series comes prewired for seamless integration with our optional Rotary Kit and the optional ALKV6-42 laser. The Axiom AutoRoute Pro V6 Series CNC routers are equipped with precision ball screws, prismatic guides, a sturdy steel frame, and an interlocking aluminum table.

In addition, the integrated MDF spoil boards ensure precise results, as they can be effortlessly milled flat to maintain a true perpendicular surface to the spindle.

Operating your CNC router without connecting it to your computer is hassle-free. Just transfer your file to the handheld controller using a USB storage device. The RichAuto B18 controller, lightweight and powerful, offers a decade of proven performance in demanding applications, making it effortless to operate.

| X axis travel | 24" (610mm) |

| Y axis travel | 24.1" (610mm) |

| Z axis travel | 5.9" (150mm) |

| C axis travel | 360deg |

| Table work area | 28.4" x 39" |

| Spindle Configuration | ER20 |

| Included Collets | 1/4" & 1/2" |

| Electro Spindle | 2.2KW |

| Spindle speed | 0~24000 RPM |

| Rapid shuttle speed | 300 IPM (5 MPM) |

| Precision Linear Guideway | X/Y/Z |

| Precision Ball Screw | X/Y/Z |

| Ball Screw Diameter | 16mm |

| Resolution | +/- .00393" (0.10mm) |

| Power requirements | 220 V,50~60 Hz, 10A, 1-Phase |

| Working Table | High rigidity Aluminum Extrusion |

| Gantry bridge | High rigidity Aluminum Extrusion |

| Gantry Supports | Aluminum alloy gravity cast |

| Gantry Clearance (from table) | 6.5" (165.1mm) |

| Gantry Clearance (from mdf spoil board) | 5.5" (139.7mm) |

| Machine Base | All Welded Steel |

| Frame Machine Dimensions | 39.17"L x 37.36"W x 30.27"H |

| Shipping Dimensions | 42"L x 39"W x 33"H |

| Shipping Weight | 320 lbs |

| Tool Touch-Off Device | Included |

| Onboard Cooling System | Included |

| Pre-wired for ALKV6-42 laser | Included |

| Controller | Richauto B18 DSP 4-Axis Controller CNC motion control system USB port for easy file transfer. |

| Language | Support English / Chinese |